Specifications

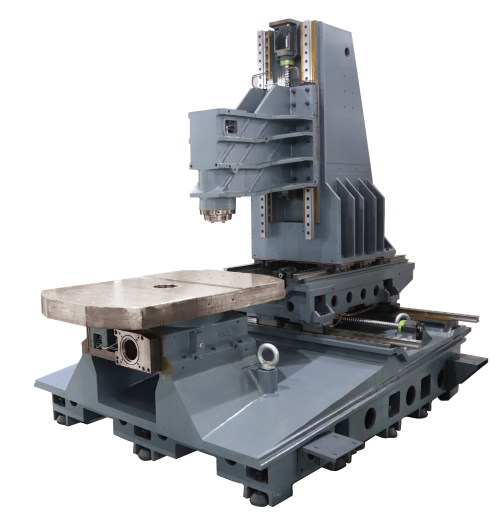

VD-8iB APC

| Travel | X - Axis Travel | 800mm | |

|---|---|---|---|

| Y - Axis Travel | 500mm | ||

| Z - Axis Travel | 560mm | ||

| Spindle Center To Z - Rail | 620mm | ||

| Spindle Nose To Table | 120 - 680mm | ||

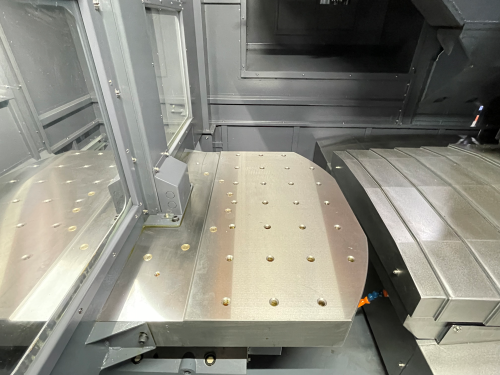

| Table | Table Size | 2-800 X 450mm | |

| T - Slot (number*width*pitch) | M16*120mm*100mm | ||

| Maximum Table Load | 300kg X 2 | ||

| Automatic Pallet Changer | The Workbench Number | 2 Pallets | |

| Table Change Time | 6 sec | ||

| Rotary Way | 180° | ||

| Spindle | Spindle Taper | BT-40 | |

| Spindle RPM | 50-12000rpm | ||

| Type Of Driving | Direct Type | ||

| Feed Rate | X. Y Axis Rapid Feed Rate | 36m/min | |

| Z Axis Rapid Feed Rate | 36m/min | ||

| X. Y. Z Max.Cutting Feed Rate | 10m/min | ||

| Automatic tool changer | Arm Type (Tool to Tool) | 24T (3sec) | |

| Max. Tool Diameter*Length(adjacent) | Φ150X300mm(Φ78X300mm) | ||

| Max. Tool Weight | 8 kg | ||

| Motor | MITSUBISHI | FANUC | |

| Spindle Motor | 11/18.5kW | 11/18.5kW | |

| X. Y Axis Servo Motor | 3.0kW | 3.0kW | |

| Z Axis Servo Motor | 3.0kW BS | 3.0kW BS | |

| Machine Accuracy | Positioning Accuracy (JIS) | ± 0.005mm / 300mm | |

| Repeat Poitioning Accuracy (JIS) | ± 0.003mm | ||

| Others | Approximate Weight | 9000kg | |

| Floor Space Measurement | 2550*3385*2950mm | ||

Above specification are subject to change without prior notice.

Standard Accessories

| FANUC 0i-MF Plus 10.4" LCD screen |

| Spindle coolant system |

| Around spindle cutting coolant unit |

| Heat exchanger for control cabinet |

| Chip flush/Back chip flush |

| Auto lubrication system |

| Auto power off/Rigid tapping |

| Work lamp/Three color light |

| Air blast through spindle |

| CF card interface |

| Remote manual pulse generator(MPG) |

| High pressure coolant & air gun |

| Leveling screws with blocks |

| Tool box & Tool |

| Full splash guard |

| System operation and procedures manual |

| Machine Manual |

Optional Accessories

| Mitsubishi controller |

| BT40 Direct type spindle 12000rpm |

| Arm type ATC (24T/30T) |

| Chain type chip conveyor with cart |

| Tool length mesurement system |

| Coolant through spindle (30bar/50bar) |

| Three axis optical scale(HEIDENHAIN)) |